Concept

Challenge of Solar Panel Waste

Globally, PV waste is expected to skyrocket from 400,000 tonnes in 2020 to over 5.5 million tonnes per year by 2050.

Yet, current recycling methods fall short, recovering only the most basic components, such as aluminum frames and contaminated glass.

As a result, valuable materials like silicon, which accounts for 40% of a module’s cost, and other metals such as silver, are rarely recovered. This means that most of the panel’s true value and its potential for reuse are lost.

APOLLO aims to transform this and recover these valuable metals.

APOLLO’s Mission

APOLLO is redefining how we think about solar waste. It pioneers a circular economy approach that links:

Legacy recycling

Future PV module production

Next-generation recycling systems

Using these five key processes, APOLLO increases recovery rates from 18% to 93%.

It all starts with sorting PV waste, extraction, refining, reusing, and tracing materials with blockchain-based transparency.

PV WASTE

Value chain

At the core of the APOLLO value chain is the APOLLO Micro Factory, which is designed to recover valuable materials from end-of-life solar panels. In collaboration with existing recycling facilities, the factory will process 40 tonnes of photovoltaic (PV) waste to extract high-purity materials, including critical metals, glass, and silicon. These recovered components will then be refined through ingot growth and wafering. Using these recycled materials, new solar panels will be manufactured for end users, creating an effective circular economy model for the photovoltaic sector.

Objectives

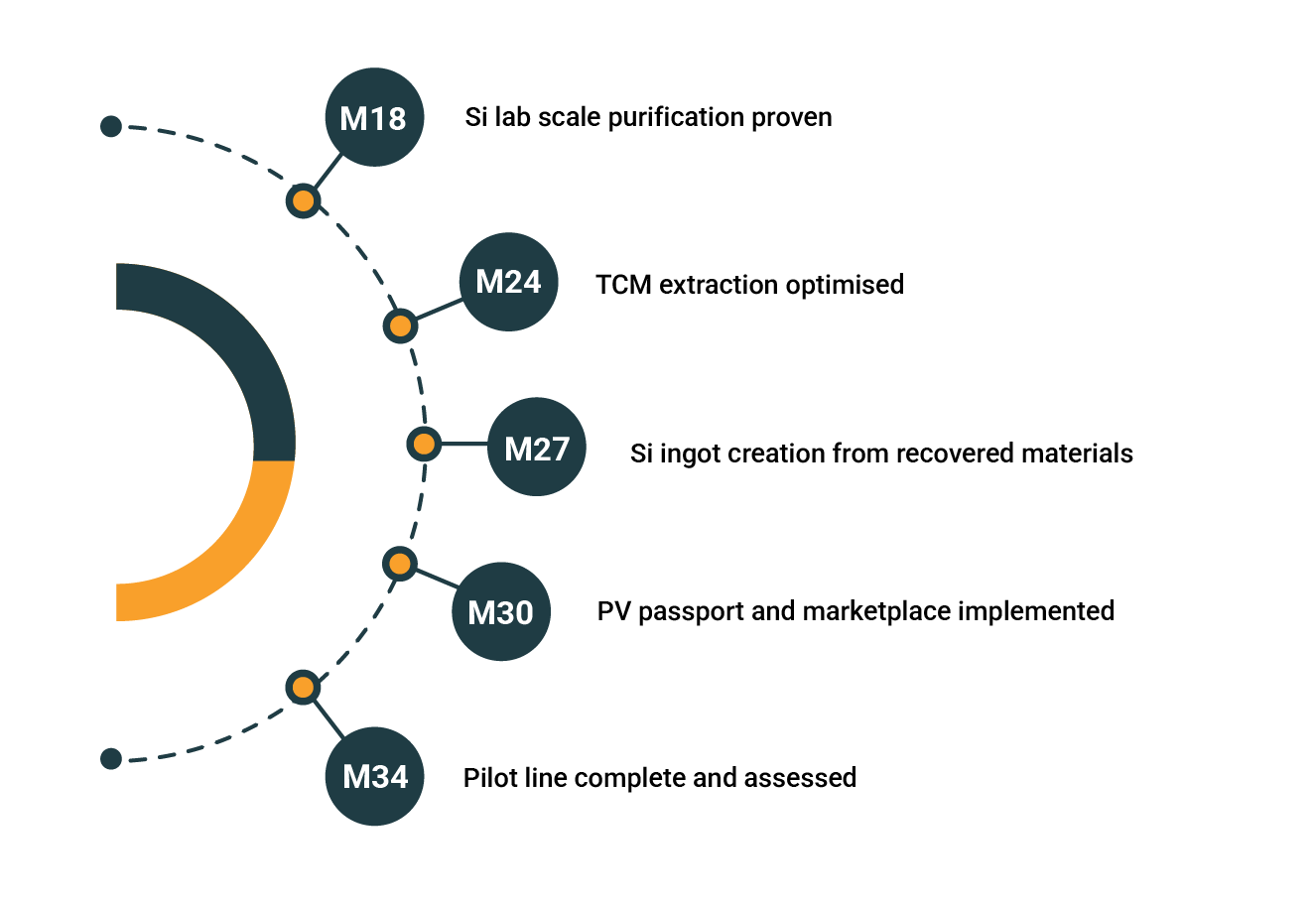

Pre-recycling analysis and classification of PV modules by glass composition

Pilot processing line to extract all of the material fractions of legacy and future PVs

Refinement of reclaimed PV Si to facilitate ingot growth for new PV

Specify and build future PV modules (standard c-Si and tandem Per/Si) with improved recyclability incorporating APOLLO innovations

Develop and implement a PV-centred Digital Product Passport (DPP) facilitating an online marketplace

Develop, quantify and promote a new circular business model for waste PV